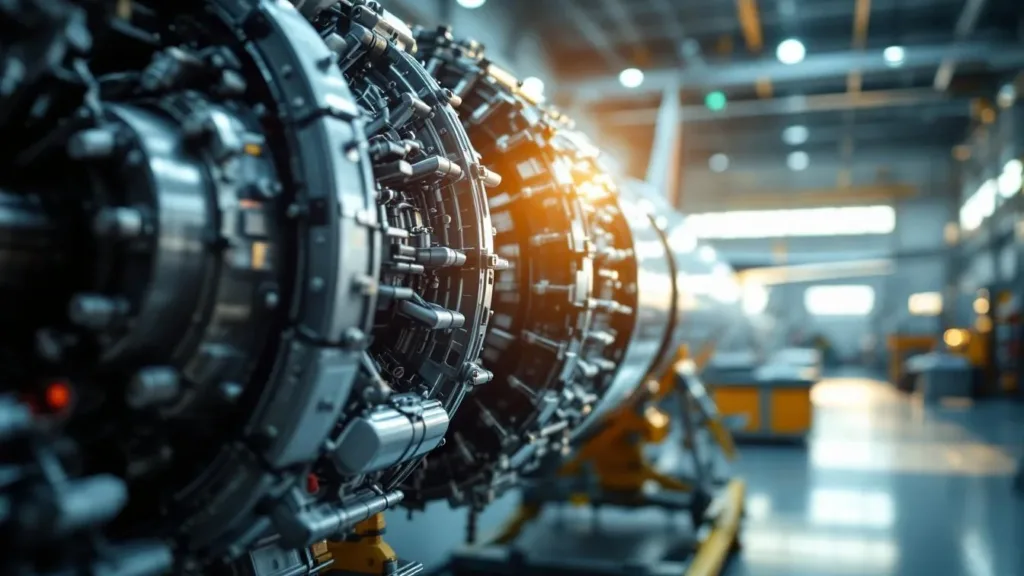

When it comes to the costs associated with keeping an aircraft in the air, many might be surprised to learn just how expensive certain components can be compared to everyday vehicles. In an era where fuel efficiency and maintenance costs are under constant scrutiny, a particular aircraft part has emerged as one of the most expensive to maintain, surpassing even the costs associated with the average car. Understanding these expenses sheds light on the high stakes of aviation maintenance and offers perspective on what it really means to keep an aircraft operational.

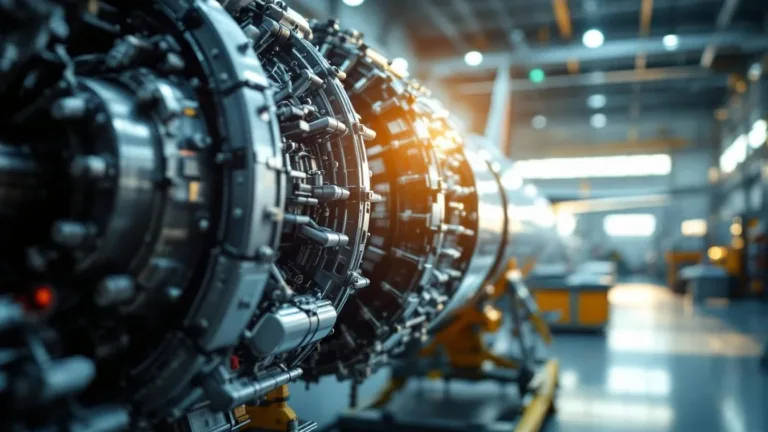

Aircraft engines, specifically turboprop engines, highlight the significant financial commitment required from operators. While piston engines tend to be more economical, providing an attractive option with lower fuel and maintenance costs, turboprops come with the benefit of enhanced performance and reliability. The argument often boils down to this: although turboprop engines are known for their longevity, the costs of overhauls can easily reach tens of thousands of pounds—far beyond any routine automotive repair. In fact, the annual ownership cost for even the cheapest turboprop can surpass £100,000, not including operational hours.

Comparing Maintenance Costs: Aircraft vs. Car

This stark contrast can be illustrated through a direct comparison between popular aircraft: the Cessna 208, a well-known turboprop, costs approximately £1,100 per hour to operate. In contrast, its piston-powered counterpart, the Cessna 421C, comes in at around £800 per hour. While both serve their purpose, the financial implications of using a turboprop versus a piston engine become evident very quickly.

The maintenance costs for aircraft parts are not uniform; they vary significantly based on the type of engine and its age. Turboprop engines, despite offering advantages in propulsion, demand more extensive and costly maintenance procedures due to their complexity. Furthermore, as these engines are pushed to their operational limits, the requirement for parts replacement can skyrocket, highlighting the need for a comprehensive understanding of engine performance and reliability.

The Long-Term Implications for Aircraft Owners

In aviation, the choices made regarding engine types can have lasting effects on financial sustainability. While the upfront costs for purchasing turboprop engines might be higher, their operational efficiency and reliability could justify the investment in the long run. However, owners must remain vigilant about the ongoing maintenance costs that can mount significantly over time.

The rising trend towards electric aircraft offers a glimpse of hope for reduced maintenance costs, but the technology remains in its infancy. Current electric systems promise to slash operating costs, but their adoption still faces hurdles. For now, the discussion primarily centres on the current realities of piston versus turboprop engines, with an emphasis on understanding which option suits specific operational needs best.

Understanding Maintenance Requirements

Beyond costs, the maintenance requirements for aircraft vary dramatically. Regular checks, compliance with aviation regulations, and the careful monitoring of engine performance play crucial roles in ensuring airworthiness. The mechanics charged with these responsibilities face a blend of challenges that require both skill and an in-depth understanding of the aircraft’s operational parameters.

Moreover, as aviation technologies continue to evolve, the demand for skilled mechanics capable of servicing modern aircraft will only grow. The complexity of today’s engines demands continuous learning and adaptation to new maintenance practices, further adding to the long-term costs associated with both training and tool acquisition.

Final Thoughts on the Future of Aircraft Maintenance

As the aviation industry navigates through advancements in technology, the conversation regarding the cost of aircraft maintenance remains ever-relevant. Understanding the factors that contribute to these costs—particularly for engine types—can empower operators to make informed decisions about their investments. As electric aircraft innovations inch closer to practicality, the hope is that they will transform maintenance costs entirely, setting a new standard for efficiency and financial viability in aviation.